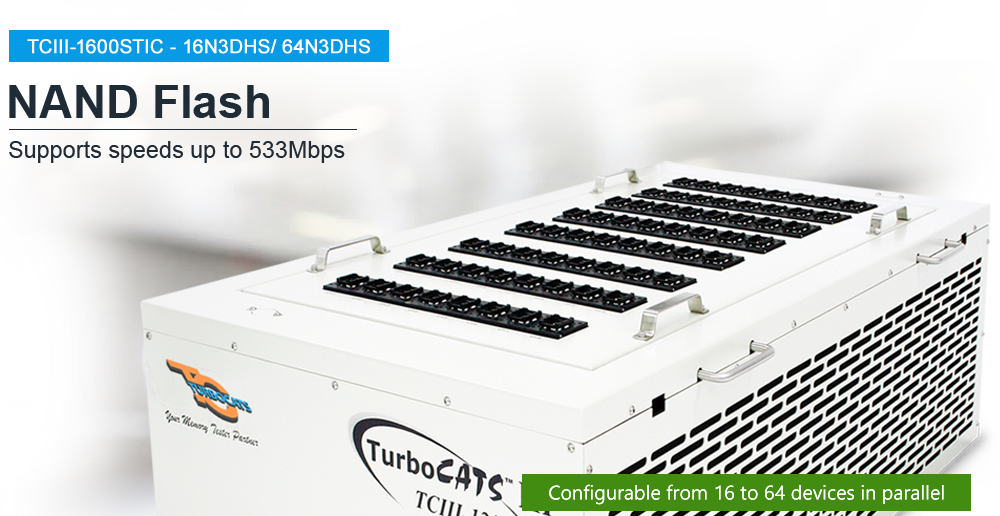

TCIII-1600IC NAND Flash Test System

Testing 16/64 IC's in parallel and at speed

The TCIII-1600IC NAND Flash test system comes with 16 or 64 DUTs. 16 or 64 DUTs can be tested in parallel to provide faster production. Error logging on Block/Page/Column and DQ's is also available. An optional handler interface allows the tester to communicate to a handler that perform ICs sorting and binning after testing.

NANDFlash IC

- 2D NANDFlash speeds up to 200Mbps

- 3D NANDFlash speeds up to 800Mbps

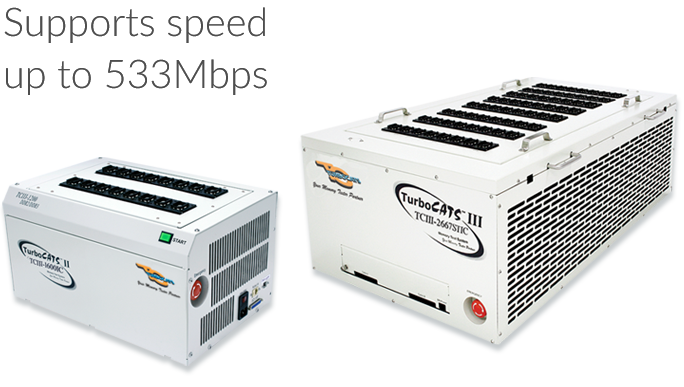

NEW! Considering an upgrade to 3200Mbps?

Need a reason to upgrade your current memory testing environment to DDR4/LPDDR4 speeds of up to 3200/2667 Mbps and DDR3/LPDDR3 speeds of up to 1866 Mbps. Click here to learn more about the TCIII-3200IC test system.

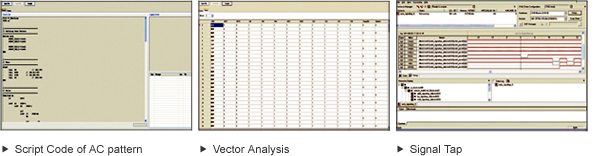

Script Code Function (optional)

Script Code Debugger

Traditional test systems provide the user with a variety of AC test patterns to use in their testing process. If a customer wanted the capability to generate a proprietary test pattern, they would have to purchase a high-end automated test system. For most companies this is cost prohibitive and not a viable option.

TurboCATS introduces the new feature called "Script Code" in its new test system, the TCIII-1600IC. The customer can now use the script programming language to create a customized test pattern. Once the pattern is created, the "Script Code" pattern generator/compiler is used to compile the code, then generate the new test pattern.

The "Script Code" function also contains a built-in compiler and debugger for the "Script Code" programming, which allows the customer to monitor the timing waveform of the programming algorithm as well as the timing bus transactions. This is all accomplished under the "Signal Tap" tool.

The new pattern is then imported into the test list and gives the customer a customized pattern with AC (tSU, tWD, tSAC, tRCD, tCL, tAL, tWR, tRP, tRC, tREF, tRFC, etc.) and DC (Vdd, Vref) parameters for testing their product. Additionally, the customer can also create a motherboard test pattern algorithm using the "Script Code" function. The TCIII-1600IC performs the test with no-wait states in the operating system.

Utilizing the "Script Code" function gives the customer a high degree of flexibility in terms of timing bus programming for creating unique Read and Write programming transactions under best and worst case AC parameters scenarios. This can also be used to create a no-wait state bus transaction in the Read to Write cycle.

Combination of Failures

Powerful Integration Tool

- Functional Failure: Cell stuck-at, coupling, neighborhood sensitivity and software error faults

- Parametric Failure: (AC) Speed timing vs. Vdd threshold, (DC) Leakage and Idd's

- Hot-Temperature Failure: System high temperature environment

Heat Chamber (optional)

Ideal solution for high-performance testing

- Seven-segment Temperature Display

- Temperature Setting Option

- Temperature Range (85°C - Room Temperature)

- Pneumatic Control System

- Automatic level-control, manual operation not required

Features:

NandFlash IC

- 2D NANDFlash speeds up to 200Mbps

- 3D NANDFlash speeds up to 800Mbps

- Operating clock frequency from 100MHz to 400MHz

- Configurable for testing 16 or 64 IC's, in parallel and at speed

- IC components and custom test socket load boards

- Supports open/shorts testing

- Supports leakage tests for IC testing

- Supports AC/DC parametric

- Supports integrate the use with Signal Tap software

- User-defined Script Code test pattern programming

DC Function - Power short and Leakage test

AC Function

- CID (Device identification) register read

- CSD (Device-Specific Data) register read

- Extended CSD register read

- User area erase

- User area data write - Single block write & Multiple-block write

- User area data read - Single block read & Multiple-block read

- Supports HS200 and HS400 mode

Other (optional)

- Configurable for testing 16 or 64 IC's, in parallel & at speed

- IC components and custom test socket load boards

- Supports open/shorts testing

- Supports leakage tests for IC testing

- Supports AC/DC parametric

- Supports integrate the use with Signal Tap software

- Supports built in "industrial standard" and "standard MB program," AC patterns

- User defined script code test pattern programming

- Error logging up to 64 locations of Row/Column/BA/Burst/DQ's

- Optional heat chamber for hot environmental testing from 32°C to 85°C

Minimum PC Requirements

- Windows 7 or later and networking interface

AC Power Supply

- 110 -240 VAC, 50/60 Hz

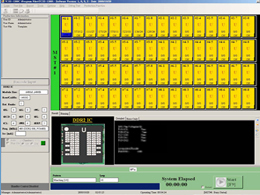

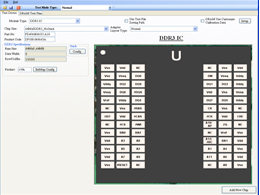

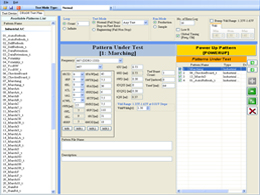

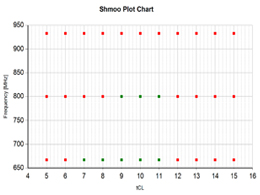

Software Screenshots:

Main Operating Window

Test Device

Test Plan

Shmoo Plot

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.