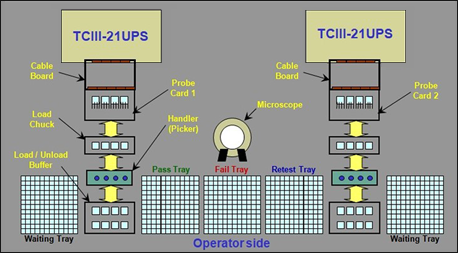

TCIII-21UPS Die Probing Station

Get the technology you need to grow

Testing Capabilities

Built to fit your memory testing needs

- DDR3/ DDR4/ DDR5

- LPDDR2/ LPDDR3/ LPDDR4/ LPDDR5

- NAND Flash

- Supports speeds up to 400Mbps

How It Works

- Supports high productivity and enhances efficiency of the handler system

- 2 work zones

- Supports semi-automated Die Handler with TurboCATS series

- Operator loads die on buffer plate and starts the test

- Prevents Probe Card damage during load and unload operations

- Prevents contact fail due to improper alignment

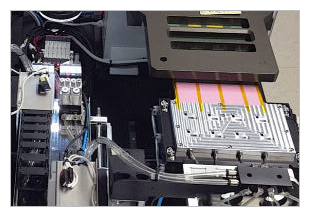

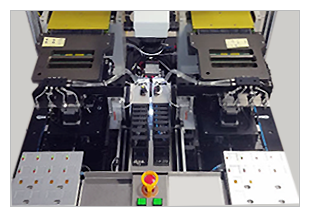

Power Up with the Semi-Automated Die Handler

Stable handling for small packages

Features & Specifications

DDR3/ DDR4

| DDR3 | DDR4 | |

| Test Frequency | Speed up to 200MHz | |

| Switching Data Rate | Speed up to 400Mbps | |

| I/O Interface | SSTL-15, Class I & Class II SSTL-135, Class I & Class II |

POD12-1.2V Pseudo Open Drain I/O |

| Clock Lines | 1 pair | |

| Address Depth | 16 Rows, 15 Columns, 3 BAs 16X/ 15Y/ 3Z per site |

17 Rows, 15 Columns, 4 BAs 17X/ 15Y/ 4Z per site |

| Data Width & Depth | 8 I/O, Support 8/ 16/ 32 bit IC devices | |

| Control | 2 CS's, 2 CLKE, 1 RAS, 1CAS, 1WE | |

| Termination | On-chip, dynamic | |

| Variable Timing Edges | tSU/ tHD, tWD, tDQSS, tAC, etc | |

| Programmable Timing | tRCD, tRP, tCL, tAL, tCWL, tWR, tRL, tWL, tRFC, etc. 1 pair of clock per IC socket |

|

DDR5

| Test Frequency | Speed up to 200MHz |

| Switching Data Rate | Speed up to 400Mbps |

| I/O Interface | 1.1V DRAM I/O |

| Clock line | 1 pair per site |

| Address Depth | DDR5 17 Rows, 10 Columns 3/2 BG/BA per site |

| Data Width & Depth | x8/ x16 bit IC device |

| Termination | On-chip, dynamic |

| Variable Timing Edges | tSU/tHD, tWD, tAC, Tsref, Tref etc |

| Programming Timing | tRCD, tRP, tCL, tAL, tCWL, tWR, tRL, tWL, tRFC, etc 1 pair of clock per IC socket |

LPDDR2/ LPDDR3/ LPDDR4

| LPDDR2 | LPDDR3 | LPDDR4/4X | ||

| Test Frequency | Speed up to 200MHz | |||

| Switching Data Rate | Speed up to 400Mbps | |||

| I/O Interface | 1.2V HSTL Class | 1.2V HSUL | Support LVSTL | |

| Clock Lines | 1 pair | |||

| Address Depth | 14 Rows, 10 Columns, 3 BAs | 16 Rows, 15 Columns, 3 BAs | 17 Rows, 10 Columns, 3 BAs | |

| Data Width & Depth | 8 I/O, Support 8/ 16/ 32 bit IC devices | Support 16/ 32 DQs | ||

| Control | 2 CS's, 2 CKE, 10 CA | |||

| Termination | On-chip, dynamic | |||

| Variable Timing Edges | tSU/ tHD, tWD, tDQSS, tAC | |||

| Programmable Timing | tRCD, tRP, tWR, tRL, tWL, tRC, tRTP, tRFC, etc. 1 pair of clock per IC socket |

|||

NAND Flash

| Test Frequency | Supports 100 and 200MHz | |||

| Switching Data Rate | Supports 200 and 400Mbps | |||

| I/O Interface | ONFI 1.0, ONFI 2.0, ONFI 3.0, Toggle NANDFlash | |||

| Control | Async: CE#, R/B#; RE#, ALE, WP#, CLE, WE# | |||

| NV-DDR: CE#, R/B#; W/R#, ALE, WP#, CLE, CLK, DQS | ||||

| NV-DDR2: CE#, R/B#, CLE, ALE, RE, WR, WP#, DQS | ||||

| Variable Timing Edge | tDS, tDH | |||

| Programming Timing | Async: tCLS, tCLH, tALS, tALH, tWP, tWH, tDS, tDH, tWC, tADL, tCH, tWW, tCS, tRP, tRC, tREA, tRR, tOH, tWHR, tAR, tWB, tREH, tRHW, tWHR2, tBERS, tR, tPROG | |||

| NV-DDR: tADL, tCAD, tCALS, tDS, tCCS, tDQSCK, tDQSS, tRHW, tWB, tWHR , tWW, tWPRE, tWPST, tBERS, tPROG, tR | ||||

| NV-DDR2: tADL, tCALS, tCALH, tCS, tCH, tAR, tRR, tWB, tWHR, tWC, tWP, tWW, tWHR2, tWPRE, tCAS, tCAH, tCDQSS, tCDQSH, tWPST, tWPSTH, tRPRE, tDQSRE, tRPST, tRPSTH, tBERS, tR, tPROG | ||||

| DC Tests | DC Open, Shorts/ Leakage, Idds Measurement | ||||

| System & Software Features | DC & AC Parametric Test:

|

||||

GUI Failure Analysis Tool:

|

|||||

Flexible Configuration : Configurable from 6 to 512 sites for parallel test on production floor.

|

|||||

Semi-Automated Die Handler:

|

|||||

| Control PC | Windows 8 operating system (64 bit) or better, Networking interface | ||||

| AC Power Source | 110-240VAC, 50/60Hz | ||||

| External PC Requirements | Executes software to control station operation. Windows 8 operating system (64 bit) or better, i7-core or above, 8G RAM or above, CD ROM, LAN port x2, USB port, monitor with 1920 x 1080 resolution or higher, keyboard, mouse, display card or on-board display |

||||

| Temperature Limitation | 16°C to 32°C (60.8°F to 89.6°F) | ||||

| Humidity Limitation | 20% to 80% | ||||

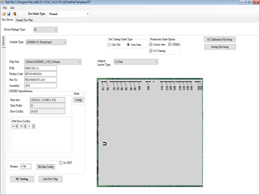

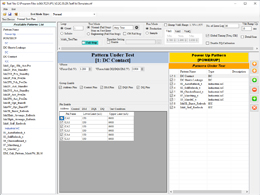

Software Screenshots

Main Operating Window

Test Device Configuration

Edit Device Page

Security Privilege

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.