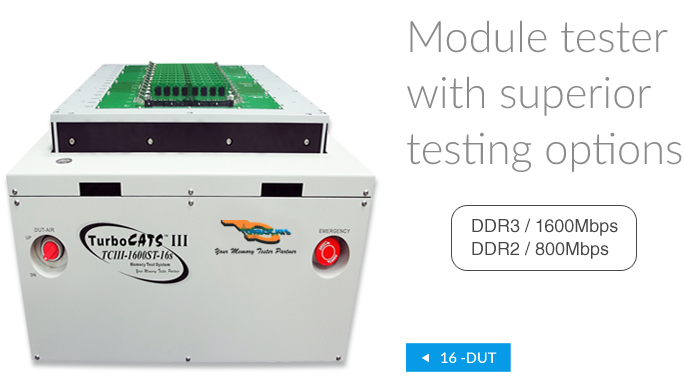

TCIII-1600ST DDR1/2/3 & SDRAM DIMM Tester

Next Generation System for DIMM Testing

High-end ATEs are designed to detect functional and AC/DC parametric failures but do not identify or pinpoint potential in-system failures. Most in-system failures caused by functional and timing compatibility issues that are generated by the system chipset. Many in-system device failures occur during system boot up or during the specific testing operation within a given system.

DWith the ability to test 16 modules in parallel and at speeds up to 1600Mbps, the TCIII-1600ST will meet the needs of an engineering group while being the ideal ATE for the production floor as well.

To effectively perform functional testing and in-system compatibility testing, most memory manufacturers incorporate a costly two (2) step testing process as part of their Standard Operating Procedure (S.O.P.).

- Functional and parametric testing

- In-System testing utilizing motherboards

One of memory manufacturers' most difficult challenges is finding a cost effective method of testing their products so they can minimize the time to market and field failures/ returns. To facilitate this costly and time consuming process, they must incorporate the two (2) step testing method. Capital expenditures, for the equipment and manpower required to perform this extensive testing, often result in budget overruns for various cost centers.

Powered for productivity

- DDR3 - 800Mbps, 1066Mbps, 1200Mbps, 1333Mbps, 1600Mbps [ 240P LODIMM, 204P SODIMM, 204P SODIMM, 240P DIMM LRDIMM ]

- DDR2 - 400Mbps, 533Mbps, 667Mbps, 800Mbps [ 240P LODIMM, 200P SODIMM, 200P SODIMM ]

- DDR1 - 200Mbps, 266Mbps, 333Mbps, 400Mbps [ 184P LODIMM, 200P x32 LODIMM ]

- SDRAM - 200Mbps, 266Mbps [ 168P LODIMM ]

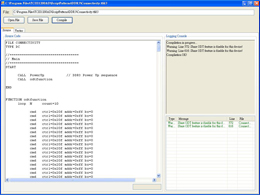

Script Code Function (optional)

Script Code Debugger

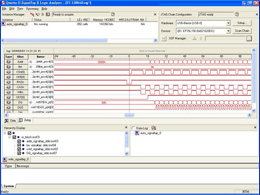

TurboCATS offers a new feature called "Script Code" in its new test system, the TCIII-1600ST. In this new system, the customer can use the script programming language to create a customized test pattern. Once the pattern is created, the "Script Code" pattern generator/compiler is used to compile the code and then generate the new test pattern.

The "Script Code" function also contains a built-in compiler and debugger for the "Script Code" programming, which allows the customer to monitor the timing waveform of the programming algorithm as well as the timing bus transactions. This is all accomplished under the "Signal Tap" tool.

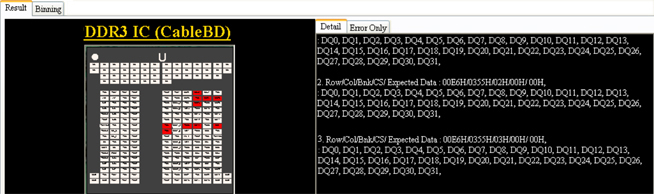

Bit Failure Mapping

Bit failure mapping is a tool that helps users find the failed DQ bits in the RAM. The corresponding row and column addresses the failed DQ bits, which will be displayed conveniently for the user with the aid of diagrams.

The failed Bank is spotted (Figure 1) and then the user can find the location of the failed DQ bit (Figure 2) if the user double-clicks the failed Bank.

Enhanced DC (VSIM & ISVM)

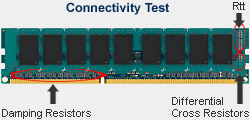

1. Voltage Sense and Current Measurement (VSIM)

This will detect shorts on the signal line as well as detect proper values of resistor packs and discrete resistors to Ensure that proper values are used in all places and properly mounted.

2. Current Sense and Voltage Measurement (ISVM)

A pattern that will detect any open pins on the contacts between test sockets and DIMM's before functional testing begins. This pattern will also detect any open pins on both passive and memory components on the PCB.

3. System Power Short Protection

4. VREFCA / VREFDQ

Voltage ref short detection including programmable VREFCA and VREFDQ.

Heat Chamber (optional)

Efficiency and high-performance

- Seven-segment Temperature Display

- Temperature Setting Option

- Temperature Range (85°C - Room Temperature)

- Pneumatic Control System

- Automatic level-control, manual operation not required

Features:

| DDR3 - PC6400 (800Mbps), PC8500 (1066Mbps), PC10600 (1333Mbps) & PC12800 (1600Mbps) |

| DDR2 - PC3200 (400Mbps), PC4200 (533Mbps), PC5300 (667Mbps) & PC6400 (800Mbps) |

| Operating clock frequency from 200Mhz to 800Mhz |

| 8 or 16 test sockets available for faster thru-put in a production environment |

| Form factor supports: 240P LODIMM, 200P SODIMM, 204P SODIMM, IC components, custom form factors |

| Single adapter supports both unbuffered and registered module testing |

| Supports LRDIMM testing, with voltage supply 1.35v - 1.5v & clock frequency 400Mhz - 800Mhz |

| Supports AC/DC parametric and user script pattern programming |

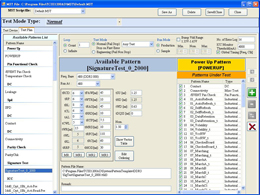

| Supports SPD programming, read, test and write-protect |

| Over 35 industry standard AC test patterns available to the end user to customize their test lists |

| Error logging up to 512 locations of Row/Column/BA/Burst/DQ's |

| Optional 8 or 16 module testing, in parallel, for high throughput on production floor |

| Optional heat chamber for hot environmental testing from 32°C to 85°C |

| Optional handler interface is available for combining the TCIII-1600ST with an automated handler |

AC Specifications:

| Test Frequency | DDR2, 200Mhz - 400Mhz DDR3, 400Mhz - 800Mhz |

| Switching Data Rate | DDR2, 400Mbps - 800Mbps DDR3, 800Mbps - 1600Mbps |

| I/O Interface | DDR2, SSTL-18, Class I & Class II DDR3, Class I & Class II |

| Clock Lines | 3 pairs per site, up to 16 sites |

| Address Depth | 16 Rows, 15 Columns, 3 BA's, 16X/15Y/3Z per site, up to 16 sites |

| Data Width | 72 I/O's per site, up to 16 sites |

| DQS's | Differential & single-ended |

| Control Lines | 4 CS's, 4 CLKE, 1 RAS, 1 CAS, 1 WE per site, up to 16 sites |

| Termination | On-chip, dynamic |

| Variable Timing Edges | tSU/tHD, tDS/DH, tAC |

| Programmable Timing | tRCD, tCL, tRL, tWL, tAL, tRP, tRFC, tWR, tCWL, etc. |

| SPD Program | Read, Program, Edit, Test, Serialization, Write Protect, Slot test, Byte Matching Test |

| Control PC Requirement | Windows 7 or better, Networking interface |

| AC Power Source | 110-240VAC, 50/60Hz |

Handler Interface

Powerful Integration

An optional handler interface allows the TCIII-2133ST module test system to communicate with a handler that performs DIMMs sorting and binning after testing.

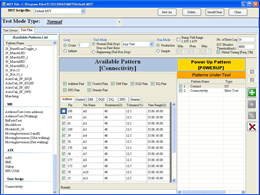

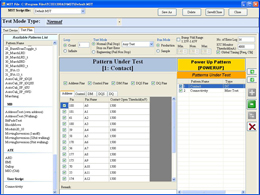

Software Screenshots:

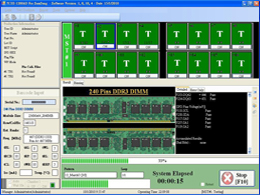

Main Screen (8-site)

Main Screen (16-site)

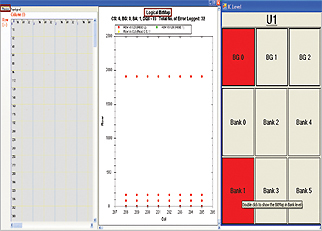

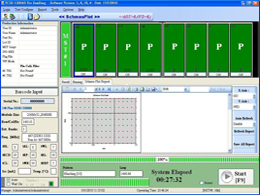

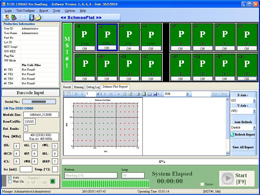

Shmoo Plot (8-site)

Shmoo Plot (16-site)

Signal Tap

Script Code

DC Connectivity Function

DC Contact Function

Test List

Security Privilege

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.